In the print industry, as important as creating a unique design, choosing a printing method, and other print requirements like size, color, paper, etc. is; finalizing a printing finish too, is a crucial decision to make. And if you think what’s so big deal about it then guess what? There are countless choices to take your pick from and each serves a different purpose.

So, this comprehensive guide explores various print finishing techniques, their applications, and how they can significantly impact revenue, with the help of which print service providers like you can deliver high-quality products and meet customer demands.

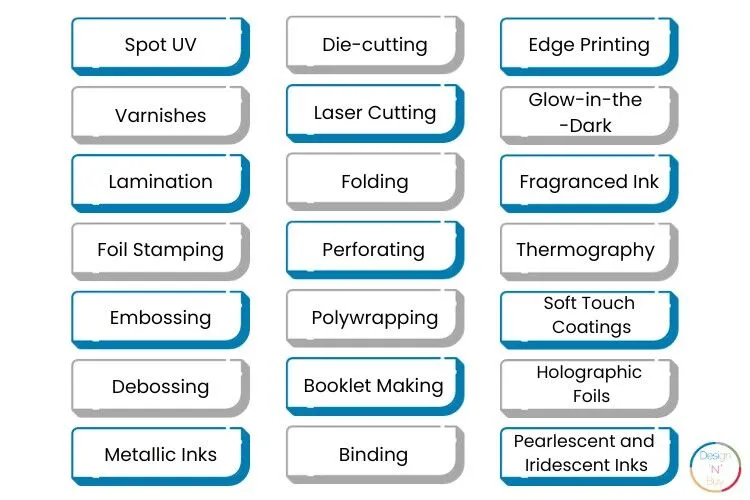

Understanding the Top 21 Print Finishing Techniques and Their Applications

Different types of print finishes can enhance the appearance, durability, and overall quality of printed materials. Here are several common types of print finishes and the products they are often used on:

1. Spot UV

Spot UV involves applying a glossy coating to specific areas or spots, creating contrast with the matte or uncoated background. It is done to draw the user’s attention to a particular part of the design from the whole page. It is a tough, transparent coat that is applied to the printing surface and is cured or hardened by UV light during the printing process.

Applications – Business cards, brochures, packaging, and promotional materials where specific elements like logos or images need to stand out.

2. Varnishes

Generally associated with wood where it is applied for a modern, sleek look, varnishes are also used for papers for a smooth finish. They are clear coatings applied to the entire printed surface, adding a protective layer and altering the texture, without adding extra weight to the material and keeping smudges, fingerprints, and scratches off your finished product.

Applications – Magazines, catalogs, packaging, and promotional materials for a glossy or matte finish, depending on the type of varnish used.

• Gloss Varnishing: Provides a shiny, reflective surface to the printed material and hence is best-suited for posters, high-end brochures, packaging, and marketing materials for a vibrant and glossy appearance.

• Matte Varnishing: Offers a non-reflective, smooth surface with a soft appearance. Suitable for business cards, invitations, book covers, and luxury packaging for an elegant and understated finish.

• Silk Varnishing: Provides a silky, smooth texture to the printed surface. Used for book covers, high-end catalogs, and packaging for a royal experience.

• Machine Sealing: An invisible thin covering that does not make a visible difference to the printed products but enhances durability and protection for a longer period. It seals the ink on the paper, usually matt and silk as they are less absorbent. Suitable for packaging, labels, and promotional materials for added resilience and longevity.

DesignNBuy Is The Best Software For Label Print Shops

Label printing software seamlessly integrates all these features into a unified platform, streamlining the user experience.

3. Lamination

Lamination involves applying a thin layer of plastic film, often glossy or matte, to printed materials, providing durability and protection against water, wear, and tear. It makes the images on the print look sharper, lending it a smooth finish.

Applications – Menus, ID cards, bookmarks, and outdoor signage for waterproof and durable prints.

4. Foil Stamping

Also known as foil printing and foil blocking, foil stamping applies a malleable metallic material or colored foil to specific areas, with the help of heat and pressure, creating a shiny, reflective surface. It is time-consuming and expensive but the result is worth it because the text or images look extra luxurious.

Applications – Wedding invitations, greeting cards, packaging, and promotional materials for a rich and eye-catching effect.

DesignNBuy Is The Best Software For Greeting Card Printing Business

Empower your customers to express their creativity by using our greeting card design software to create their own custom cards.

5. Embossing

Embossing finish is used when you want to raise specific areas of the print to create a three-dimensional effect. With the help of a metal plate and counter, your desired text or image that you would most like to stand out can be embossed on paper.

Applications – Business cards, stationery, invitations, and packaging for a tactile and elegant appearance.

6. Debossing / Letterpress

Opposite printing finishing of embossing, debossing presses images or text into the paper, creating a depressed or indented effect instead of a raised appearance. It’s also a printing finishing also known as “letterpress” and is one of the earliest printing finishing methods.

Applications – High-end stationery, business cards, and packaging for a subtle and sophisticated finish.

7. Metallic Inks

Description – Metallic inks contain metallic particles, adding a reflective and metallic appearance to printed materials.

Applications – Posters, packaging, promotional materials, and invitations for a vibrant and alluring effect.

8. Die-cutting

Die-cutting involves cutting printed materials into specific shapes, adding visual interest. Using a steel cutting die, custom irregular or unique shapes and forms can be cut out.

Applications – Packaging, promotional materials, labels, and marketing collateral for unique and creative designs.

Kiss Cut Vs Die Cut Stickers — What’s The Difference?

Learn the differences between kiss cut and die cut stickers to choose the best options for your shop. Plus, how sticker design software can simplify the printing process for your print store.

9. Laser Cutting

A print finishing technique that uses laser beam technology to cut intricate designs or patterns into paper or other materials. Also popularly known as the “pop-up” or ”lace” card effect, laser cutting is one of the more creative print finishing options.

Applications – Invitations, signage, packaging, and promotional materials for detailed and precise cuts.

10. Folding

Folding involves creasing and folding printed sheets into specific shapes or formats. There are different ways for folding techniques like the basic ones – Half-folding, Tri-folding, Z-folding, Gate-folding, Roll-folding, etc. In fact, there are not many limitations to folding.

Applications – Brochures, pamphlets, leaflets, and promotional materials for organized and compact presentations.

11. Perforating

Perforating creates small holes or slits in printed materials, allowing easy tearing along the perforated lines. It is used when one wants to create easily detachable parts or a direct mail campaign.

Applications – Coupons, tickets, forms, and promotional materials for easy tear-off sections.

12. Polywrapping

Polywrapping involves enclosing printed materials in plastic film for protection and mailing purposes. It is fast, economical, and highly efficient and also the better option for protecting its content from external damage caused by water, dust, etc.

Applications – Magazines, catalogs, and direct mail campaigns for secure and weather-resistant packaging.

13. Booklet Making

A print finishing process that involves arranging offset printing and binding multiple printed materials (sheets or spreads) into booklets or catalogs.

Applications – Manuals, catalogs, brochures, and informational booklets for organized and professional presentations.

Integrating signage design software enhances your offerings, allowing clients to personalize signs easily and keeping your business ahead in the market.

14. Binding, Stapling, and Stitching

Similar to booklet making, binding, stapling, and stitching is done to join printed materials together with either wire, glue, or other means.

Applications – Books, magazines, reports, and catalogs for a polished and professional finish.

15. Edge Printing

Edge printing involves applying ink or foil to the edges of paper, creating a colored border. It gives a classy effect and can be done in any color, including foils and metallics.

Applications – Business cards, invitations, and high-end marketing materials for a distinctive and stylish look.

15. Edge Printing

Edge printing involves applying ink or foil to the edges of paper, creating a colored border. It gives a classy effect and can be done in any color, including foils and metallics.

Applications – Business cards, invitations, and high-end marketing materials for a distinctive and stylish look.

16. Glow-in-the-Dark

If you want to add a fun element, a glow-in-the-dark printing finish is the best option. Also known as phosphorescent or fluorescence, this method uses light-sensitive elements that absorb light energy and then re-emit them as their own light source. In simpler terms, it absorbs light and glows in the dark after exposure. It gives your prints the ability to glow in a dark room which truly makes it a standout among print finishing techniques.

Applications – Posters, promotional materials, and novelty items for creative and attention-grabbing designs, especially in low-light environments.

Your customers can easily create their favorite poster within minutes using our poster design software, which offers a wide range of features and functionalities.

17. Fragranced Ink

Fragranced ink contains scents that are released when rubbed or scratched. Used mostly by the beauty industry, the fragranced finish evokes emotion and tingles senses.

Applications – Promotional materials, invitations, and packaging for a sensory and immersive experience, often used in perfumes, cosmetics, and food packaging.

18. Thermography

Thermography uses heat to create a raised, textured effect on printed text or images. The printed surface of the paper is coated with a material sensitive to heat i.e. powdered resins, like in the old fax machines, and baked to get a visually appealing finish.

Applications – Business cards, invitations, and stationery for a captivating finish, often resembling engraved printing at a lower cost.

19. Soft Touch Coatings

Soft touch coatings create a velvety, smooth texture on the printed surface.

Applications – Packaging, book covers, business cards, and promotional materials for a luxurious and tactile feel.

20. Holographic Foils

Holographic foils create a three-dimensional, shifting visual effect when viewed from different angles.

Applications – Packaging, security documents, promotional materials, and labels for anti-counterfeiting measures and eye-catching designs.

Level up your print store with product customization. Offer personalized packaging products with our box packaging design software packed with advanced features.

21. Pearlescent and Iridescent Inks

Pearlescent and iridescent inks contain particles that create a subtle shimmering effect. In fact, all the colors of the rainbow can be replicated in this printing finish. An array of colors is visible when the finished product is viewed from different angles and lighting conditions.

Applications – Packaging, greeting cards, invitations, and promotional materials for a subtle and elegant shine, often used in designs where a touch of sophistication is desired.

Each of these print finishing solutions offers unique visual and tactile effects, allowing designers and marketers to create engaging and memorable printed materials tailored to specific applications and target audiences.

Wrapping Up: Print Finishing Technique

The choice of the right print finish can significantly impact the overall aesthetics, durability, and appeal of your project. Whether you’re designing business cards, brochures, packaging, or promotional materials, understanding the diverse range of print finishes available is crucial.

By choosing the right printing finishing options for each project, businesses can deliver exceptional results, enhance customer satisfaction, and maximize revenue opportunities.

If you’re looking for content related to printing methods, you can consider the following topics:

- Sublimation vs. Heat Transfer: Which Printing Method is Right for You?…Read More

- Offset Printing vs Digital Printing: Pros, Cons, and Considerations…Read More

- DTF (Direct to Film) Printing Business Essentials: Tools, Process, and Tips to Get it Started…Read More

- DTF vs DTG Printing: Selecting the Best Printing Method for Your Business…Read More

*This post has been updated on Sep 2024.