Client: Established Custom K-Cup Packaging Manufacturer (Las Vegas, USA)

Industry: Packaging & Printing

Solution: All-in-One Web2Print Platform

In the world of K-Cup packaging, speed and precision are everything. One of the USA’s top K-Cup suppliers, producing over a million custom-printed k cups boxes daily, realized that manual processes were slowing them down. Managing orders via emails and spreadsheets led to errors, delays, and bottlenecks.

They needed a scalable solution to streamline operations, improve order accuracy, and meet growing demand. That’s where DesignNBuy’s print shop order management software transformed their business.

By automating order management, print workflow approvals, and client interactions, they reduced errors by 40% and improved turnaround times by 30%, all while enhancing customer satisfaction.

When we visited their facility in Las Vegas, we saw the transformation in action, smoother print workflows, faster production, and a team empowered to take on even more. This is what the future of print automation looks like!

Challenges Before Implementing Web to Print Software

Before integrating DesignNBuy’s Web2Print, they faced:

- Manual Overload: Orders were managed via emails, spreadsheets, and phone calls, leading to errors and delays.

- Workflow Fragmentation: Disconnected systems slowed approvals, causing production bottlenecks.

- Client Dissatisfaction: Lack of real-time updates and self-service tools frustrated customers.

- Scaling Barriers: Manual processes made it impossible to meet rising demand without compromising quality.

Automate your print business like this K-Cup Packaging Manufacturer! Get a personalized Web2Print demo now

The Solution: Web to Print Implementation

Prior to our visit, the client adopted our web to print ecommerce solution to address their core challenges:

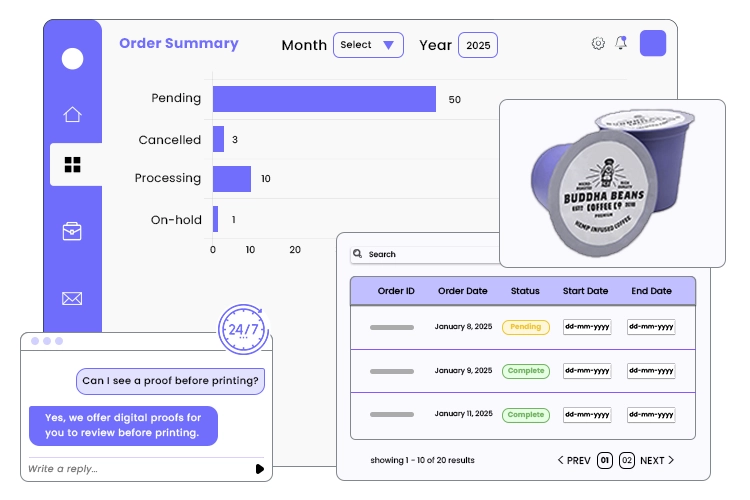

- Automated Order Management: Centralized dashboard eliminated manual entry, reducing errors by 40%.

- Streamlined Print Workflows: Customizable stages for design approvals, proofing, and production scheduling cut turnaround times by 30%.

- Client Self-Service Portal: 24/7 access to order and job tracking, artwork uploads, and real-time updates boosted satisfaction.

- Scalability: The DesignNBuy’s web-to-print platform’s flexibility allowed seamless onboarding of new clients and larger orders.

Discover how this custom K-Cup packaging manufacturer streamlined their workflow, reduced errors, and scaled production with Web-to-Print. Watch their success story here

Our Visit: Understanding Their Experience & Future Needs

During our site visit, we had in-depth discussions with their portal administrator and key team members to understand their experience with our web to print software.

It was exciting to see how our web to print solution had transformed their daily operations, making their workflow faster and more efficient. Their team shared positive feedback on the ease of use and automation in producing digital printed retail boxes and k cup packaging, but they also had ideas for further improvements.

Our discussions focused on potential feature enhancements to make the web to print system even more powerful and tailored to the unique needs as a bulk K cup supplier. The visit reinforced the value of continuous innovation and how closely we collaborate with our clients to ensure our web to print ecommerce solutions evolve with their needs.

No hidden costs, just real results. View pricing and see how Web2Print can scale your business

Final Thought

This success story shows how the right web to print technology can transform a business. By adopting web to print, this K cup packaging manufacturer has streamlined operations, improved accuracy, and scaled effortlessly to meet growing customer demands.

At DesignNBuy, we value strong partnerships and believe in solutions that grow with our clients. As we move forward, we remain committed to innovation, ensuring they stay ahead in the evolving world of print automation.