Poor packaging design cannot entice a customer into buying products. This leads to less customer retention and reduced sales.

According to a survey, 72% of consumers also stated that the product packaging design influences their purchase decisions. The stakes are high, and the print packaging competition is tough.

Every year, 64% of packaging design changes, specifically text, and barcodes. So, it’s essential to consider the challenges your print store’s current challenges and address them instantly.

In this article, we’ll give you the complete solution for these critical challenges.

7 Challenges to Overcome in Your Packaging Printing Process

A web to pack business is about reducing costs to increase margins, leading to more profits. So, if your goal is to increase your sales till the following year, consider the steps below:

1. Minimizing Packaging Transportation & Delivery Cost

The rise of E-commerce has paved the way for appealing and sustainable packaging design.

Direct shipment instead of storing the products in warehouses have given way to packaging that must be lightweight. Moreover, it also protects the products from outer elements.

For instance, replacing plastic packaging with corrugated boxes or reusable packaging will bring down the costs.

Solution:

A good solution is using packaging design software to create customized product boxes. That way, they won’t take up much space in the delivery truck, and you’ll be able to ship products in one go.

Custom inserts in the packaging can also fill empty voids and prevent damage during transit. So there is no need for secondary packaging or paying for additional security to prevent damage during transportation.

Start Free Trail

Deliver high-quality, on-demand printing with web to print software. Our user-friendly platform offers a vast selection of templates and design tools, making personalization a breeze.

2. Increasing Stacking Strength for Rigid Packaging

How to create packaging that doesn’t deform when stacked or during transit? That’s a challenge that print businesses often face.

If rigid packaging has an ample surface area, chances are that it will come in increased contact with external surfaces.

Solution:

The solution to this problem is to create rounder surfaces to reduce contact. Also, ribbing in bottles or creating stand-up pouches is an excellent way to go.

3. Developing Eco-Friendly & Recyclable Packaging

Using eco-friendly packaging is the number one challenge for printing companies. The trend for a clean green environment has given rise to packaging materials that leave no carbon footprint.

Standard laminates are made of materials that cannot be recycled. On the other hand, sustainable laminates are made of materials that can be recycled and reused. Overall, the cost of reusable materials is also low.

4. Differentiating Product through Packaging

Consumers want products that differ. From labeling to the shape and size of the packaging, everything should be unique.

If you take a traditional route, it’s most likely that your packaging design may look similar to your competitor’s.

Solution:

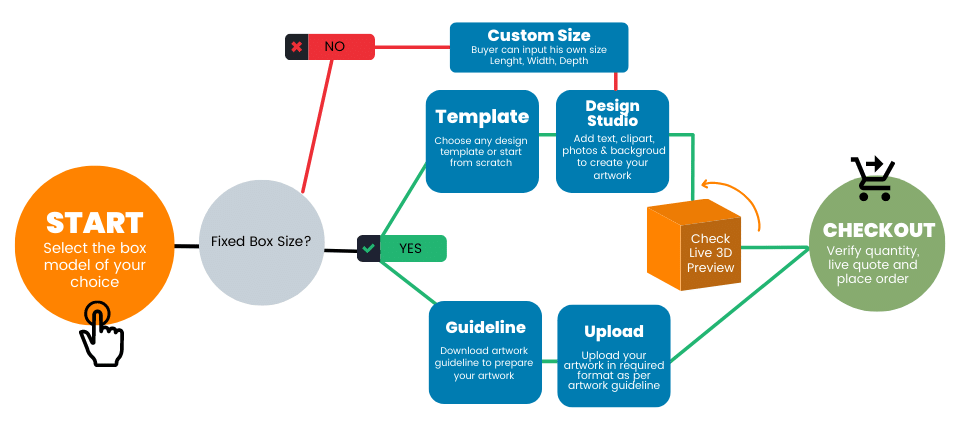

An excellent solution is incorporating packaging box design software into your print website to design unique packaging. This will also help your customers if they wish to customize designs or upload theirs.

5. Managing Workflow & Productivity

To organize physical inventory effectively, assembling a skilled team is essential to minimize dead stock and wastage risks. Once packaging is finalized, any design changes can result in significant losses if not promptly identified.

Solution:

A web2print packaging design software means you won’t have to keep a physical inventory or hire designers to keep the flow going. The software is easy to use, requires no coding, and even your customers can customize designs without any experience.

Also, you’ll only produce packaging once the order goes through. The solution is one-way, and you won’t have to manage the design for each order. This helps eliminate duplication, maintain consistency, and save costs, time, and materials. You can quickly eliminate minor errors if they happen from the print-ready files in one go without starting from scratch. This results in increased workflow accuracy.

Grow Your Packaging Print Shop Business

If you’re tired of managing multiple tools, DesignNBuy is the solution you need. Its all-in-one platform streamlines printing operations, cuts costs, and allow you to focus on what you do best, delivering exceptional products to your customers.

6. Lack of Manpower

Labor shortage poses a significant challenge in the packaging industry, where traditional methods heavily rely on manpower. From design through production, trained labor is essential to meet operational demands effectively.

Solution:

A web to print software streamlines the production process. It automates the whole process, so you won’t require a workforce to handle the workflow. The print-ready files will include all customer requirements so you can directly assign them to printers.

This will eliminate the need for labor and save time and cost. In addition, there are no chances of error, so you won’t require a team to go through eliminating each mistake.

7. Printing Process Becomes Faster

Web to pack store will speed up your production process. As the whole process is automated, the turnaround time will also reduce. You won’t have to set up machinery, check with your customers, or decide which printing method is more suitable.

The reprinting process is also more accessible because of the print-ready file. As a result, the overall speed of the printing production process will increase.

Choose the Right Web To Pack Technology To Fix Your Packaging Printing Challenges

Traditional printing services bring a multitude of challenges. But the days when printing businesses used to rely on manual labor are gone. Now’s the time for technological warfare, and the E-commerce printing competition is growing tough daily.

In this scenario, if you are running a packaging print shop, consider adopting web to pack technology to solve the critical challenges of the packaging industry.

Hopefully, our above-described solutions will help you eliminate the quagmire of reduced sales and less customer retention. Custom packaging design also appeals to customers and directly influences their purchase decisions.

Incorporating unique and sustainable packaging designs and minimizing delivery costs is the way to go if you wish to stand tall among your competitors.

If you wish to integrate a web to pack solution with your print store, DesignNBuy can help you automate the entire printing process. Moreover, it can save time, labor, and production costs and create an efficient workflow.

You can produce packaging as fast as in 24 hours. The software also provides a live 3D preview of the products so customers can check to remove doubts and personalize the design from their smart devices. You can also customize the look and feel of your packaging print shop with the help of the designer tool.

AI-Powered Design Tool in Packaging Printing for Streamlined Operations

By integrating AI into label printing processes, businesses can stay ahead of the competition. Discover how DesignNBuy’s AI-powered design tool empower your customers to create highly personalized experiences without extensive manual work.

More blogs for you:

- Top 7 Packaging Design Software for Online Print Shops…Read More

- Top 5 Label Design Software for Print Shops…Read More

- How 6 Packaging Printing Companies Grew Faster with DesignNBuy’s Web to Print Platform…Read More

- Level Up Your Web to Print Business: 10 Reasons You Need Online 3D Packaging Design Software…Read More

*This post has been updated on June 2024.