Nowadays, every business recognizes the importance of delivering excellent service to customers. Mass customization stands as a dynamic business strategy, strategically positioning itself at the intersection of efficiency and personalization. In essence, it is a paradigm that thrives on delivering personalized products and services while maintaining the cost-effectiveness associated with mass production.

Table of Contents

What is Mass Customization?

Mass customization, also referred to as made-to-order, offers customers a variety of product options. Mass customization emerged as a reaction to the increasing trend of personalization on the internet. The main idea behind mass customization is to create products or services that are uniquely tailored to each customer, fostering a sense of individuality and connection.

The core principle of mass customization lies in the creation of products or services that are uniquely tailored to each customer, fostering a sense of individuality and connection. The demand for personalized products is on the rise, with around 36% of consumers showing interest in buying items tailored to their preferences.

What is the Goal of Mass Customization?

Now, let’s talk about the goals of mass customization. Companies aim to increase product sales, enhance their manufacturing brand, boost profit margins, and engage customers more effectively.

To achieve these goals, companies use various techniques. One common approach to mass customization is giving customers a range of customizable options, allowing them to shape and design their desired product. Advanced technologies play a crucial role, making it easy to transition from standard offerings to customized products to personalized experiences.

Additionally, tapping into customer data becomes crucial for the success of mass customization. Manufacturers use comprehensive client data to understand individual preferences and needs, creating products and services that precisely match specific requirements.

This involves the implementation of digital storefronts, an online product configurator, and robust order management systems. These components work in unison, ensuring the smooth flow of information across the organization, from initial customer interactions to the final stages of production. Mass production reduces per-unit costs as output volume increases, enabling economic efficiency.

Understanding Mass Customization in Manufacturing

The realm of mass customization opens up a plethora of opportunities for manufacturers, offering a strategic avenue to differentiate products from competitors. Allowing customers the freedom to customize products not only addresses their specific needs but also creates a unique value proposition. This uniqueness, in turn, positions companies favorably in the marketplace, leaving a lasting impression on customers.

In conclusion, the adoption of mass customization as a business strategy provides several noteworthy benefits. These encompass not only heightened customer satisfaction and a nuanced understanding of customer needs but also encompass cost reduction and product differentiation.

Advantages of Mass Customization for Personalization and Mass Production

- Customer Satisfaction

- Enhanced Company Reputation

- Increased Revenue through personalized offerings

- Lowers inventory and reduces unsold goods

- Reduced Wastage

- Decreases chances of order cancellations

- Facilitates a fast and efficient production process

- Helps in understanding customers better

Allow your customers to customize and order any print product directly from your web-to-print website using the online designer tool from DesignNBuy.

Challenges of Mass Customization and Custom Production

Mass customization is a newer idea in the e-commerce business where companies aim to make customized goods for each customer without making significant changes to how they produce things.

While this can be great for customers who get more personalized products, it also comes with challenges for companies, especially in terms of costs. However, the path of mass customization is not without its challenges.

One prominent obstacle is the elevated cost compared to standard production. The production of customized products often demands skilled labor and intricate coordination within the production team, contributing to increased operational expenses.

The manual handling of data from collection to mass production introduces an element of risk, amplifying the chances of mass production errors. Robust technological solutions become imperative to centralize information, ensuring accessibility across all teams and mitigating the likelihood of errors.

Efficiently managing customer service emerges as another challenge. Timely responses to customer requests for personalized products and services, coupled with a robust order-tracking system, become paramount.

The complexity further extends to post-sales customer service, where customization considerations add layers of intricacy compared to standard products.

As manufacturers navigate these challenges, a commitment to technological innovation and streamlined processes becomes integral to the successful implementation of mass customization.

What are the Examples of Mass Customization?

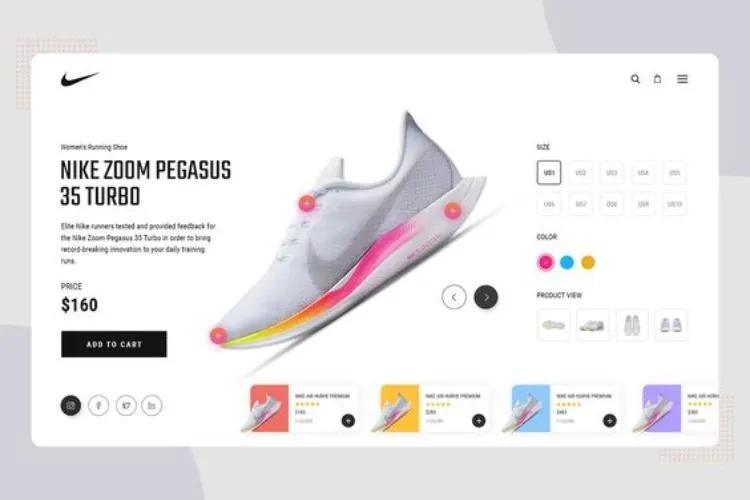

Mass customization has permeated various industries, leaving an indelible mark on how products and services are conceptualized and delivered. Renowned companies like Nike, Adidas, and Apple have embraced the trend, allowing customers to tailor products to their exact specifications. From choosing colors and materials to deciding on design elements and additional features, these companies have successfully woven the fabric of personalization adaptive customization into their offerings.

Here are the different types of made-to-order approaches:

Collaborative Customization

Collaborative mass customization is a form of mass customization where companies involve customers in the design process. This approach allows customers to actively participate in shaping the final product according to their preferences. By seeking input and collaboration, businesses can ensure that the end result aligns closely with the customer’s vision.

For examples of mass collaborative customization: Nike allows customers to design their own athletic shoes by selecting various customizable options such as colors, materials, and even adding personalized text or symbols.

Cosmetic Customization

Cosmetic customization focuses on the aesthetic aspects of a product. In this category of cosmetic customization, customers have the freedom to personalize the appearance of a product according to their style and preferences. This cosmetic customization could include choosing colors, patterns, and design elements, giving individuals a sense of ownership over the visual aspects of the product.

For examples of mass customization: M.A.C offers a program called “M.A.C Custom Palette” where customers can create their own personalized makeup palette by choosing specific shades of eyeshadows, blushes, and other products.

Adaptive Customization

Adaptive customization involves tailoring products to meet specific functional needs or preferences of customers. Companies in this category aim to provide products that can adapt to individual requirements, ensuring a more personalized and effective user experience. This form of adaptive customization often extends to features and functionalities design products.

For examples of mass customization: Fitbit offers fitness trackers that can be customized based on individual preferences. Users can choose the type of tracker, band material, and even customize the display to show the information most relevant to them.

Transparent Customization

Transparent customization emphasizes clarity and openness in the customization process. Companies adopting this approach ensure that transparent customization and that customers have a clear understanding of the options available and the impact of their choices. Transparent or transparent customization aims to build trust by providing customers with a straightforward and honest customization experience.

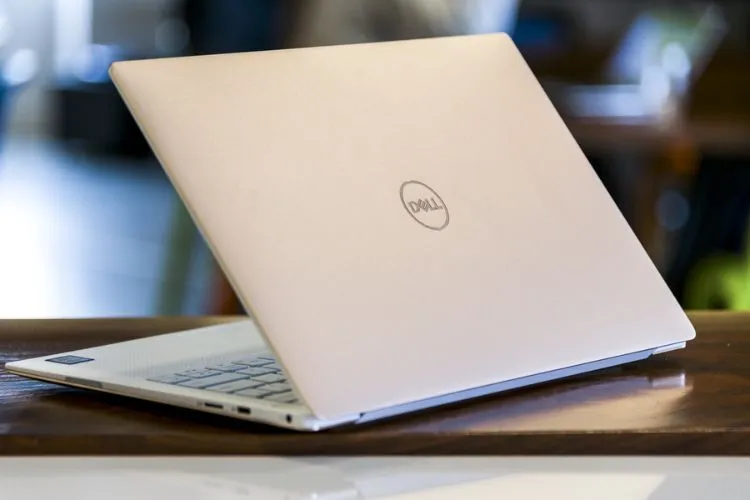

For examples of mass customization: Dell’s online platform allows customers to configure and customize their computers by selecting specifications such as processor type, RAM, storage capacity, and graphics card. The customization process is transparent, as customers can see how each selection affects the overall price and performance.

Automotive Industry

The automotive industry has witnessed a surge in customization options, allowing customers to personalize various aspects of their vehicles. This includes selecting the make and model, exterior and interior colors, and even choosing specific features or accessories. This bespoke approach to customization enables customers to own create a unique vehicle tailored to their preferences while still adhering to the cost-effectiveness of standardized production.

For examples of mass customization: Porsche offers a program called “Porsche Exclusive Manufaktur” that allows customers to customize various aspects of their cars, including exterior color, interior materials, and additional performance features.

Food Industry

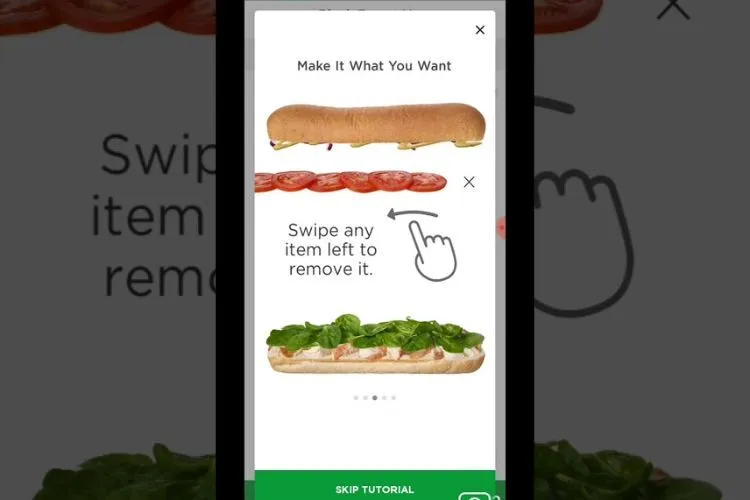

In the food industry, mass customization has become a prevalent trend. Many restaurants now offer customers the ability to customize their meals, allowing them to choose ingredients, portion sizes, and even preparation methods based on individual tastes and dietary preferences. This personalized approach enhances the dining experience, catering to the diverse preferences of customers.

For examples of mass customization: Subway, the sandwich chain, is an example of mass customization in the food industry. Customers can choose their bread, toppings, sauces, and other ingredients to create a customized sandwich tailored to their preferences.

These examples underscore the versatility of mass customization, extending its influence across diverse sectors. The ability to offer personalized experiences while optimizing production costs has positioned mass customization as a transformative force in shaping consumer interactions with products and services.

The Future of Mass Customization

As we gaze into the future, the trajectory of mass customization appears nothing short of promising. Advancements in technology are paving the way for more companies to seamlessly offer personalized products on a larger scale, rendering it an increasingly popular choice across industries.

Industries such as fashion, automotive, and consumer electronics are at the forefront of this evolution. The advent of 3D printing, laser cutting, and other cutting-edge technologies empowers companies and manufacturers to create custom items with unprecedented efficiency. In the fashion industry, for instance, companies can utilize these technologies to craft and create unique pieces tailored to individual preferences.

The automotive sector continues to leverage mass customization, with automakers providing a spectrum of options for customers to personalize their vehicles. From engine size to interior design, color, and trim, customers can now shape the aesthetics and performance of their vehicles without incurring exorbitant customization costs.

Consumer electronics giants like Apple and Samsung are also riding the wave of mass customization. Personalization options for devices, including choices in colors, designs, and features, not only make devices more unique but also enhance customer engagement.

This transformative journey is not only set to continue but is expected to become the norm in various industries in the years to come. As technology continues to evolve, companies will be better equipped to offer personalized products cost-effectively, driving a more efficient manufacturing process and cultivating a more satisfied customer base.

Online Design Tool for Custom Metal Fabrication and Wood Crafting Business

How Design’N’Buy Empowering Manufacturers

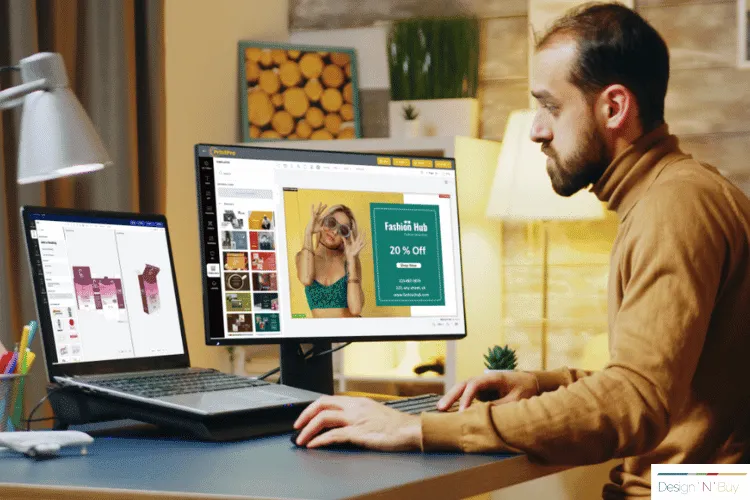

In the midst of this transformative landscape, DesignNBuy emerges as a valuable ally for companies aspiring to embrace mass customization. Offering an online product configurator and CPQ (Configure, Price, Quote) software, DesignNBuy empowers customers to personalize products seamlessly while instantly viewing pricing information.

Moreover, the Design’N’Buy team extends support to manufacturers, assisting in the comprehensive implementation of end-to-end mass customization ideas. From conceptualization to execution, Design’N’Buy ensures a smooth onboarding and customization process, enabling teams to seamlessly integrate mass customization into their production workflows. With Design’N’Buy, achieving mass customization is easy, alleviating concerns about your production schedule or stock room.Key Takeaways: Integrating Mass Customization into Your E-commerce Business

In summary, mass customization remains a compelling business idea, weaving together the realms of personalization and cost-effectiveness. It is more than a strategy; it is a dynamic force shaping the landscape of industries.

- Mass customization, as a strategic approach, seamlessly combines personalization with cost-effectiveness.

- Opportunities for manufacturers arise from the ability to differentiate products, create unique value propositions, and ultimately boost profits.

- Challenges in implementing mass customization, such as increased costs and complex customer service management, require innovative solutions and technological advancements.

- Examples of mass customization from across industries, from fashion and automotive to food and electronics, showcase the versatility and impact of mass customization.

- The future of mass customization is promising, with technology advancements enabling cost-effective personalized and customized products, in various industries.

- DesignNBuy serves as a facilitator for manufacturers, offering tools and support for e-commerce companies looking to navigate the mass customization landscape.

- As the business landscape continues to evolve, these examples of mass customization stand as a testament to the power of innovation and customer-centric strategies. The ability to offer unique, personalized experiences while maintaining operational efficiency positions companies at the forefront of consumer preferences, ensuring long-term success in an ever-changing market.

Ready to start implementing your mass customization product design strategy? Schedule a demo today to discover how DesignNBuy can help you make it happen.

Want to learn about challenges printers are facing and how to resolve them ? Continue Reading:

Overcoming Corporate Printing and Corporate Branding Challenges with Web to Print Solutions…Read More

Cross Border Shipping Challenges for Online Sign Shops & Strategies to Overcome Them…Read More

Common Challenges To Wide Format Printing: How Can Web to Print Solve These Challenges?…Read More

Top Online Business Challenges for Printers in Europe and How Web-to-Print Can Be a Solution…Read More

8 Biggest Challenges of the Packaging Industry and How Web to Pack Solves Them…Read More