Packaging is omnipresent, touching almost every person living on this planet. From food and medicines to clothes and electronic gadgets, everything is packaged. However, there have always been concerns about spoilage, authenticity, and origin. Not anymore.

As the world races towards more advanced and sustainable means of packaging, one thing is for sure that packaging is becoming more intelligent, and there is a lot of scope for printers to bank on the next level of Web-to-Packaging.

For example, thin electronic sensors monitor the condition of the product and provide information such as storage time, freshness, or temperature. That is especially helpful to know the freshness level of packaged bakery items or a packet of vegetables.

Besides, by using digital technologies such as 3D printing or scannable stickers, brands are trying to better connect with and engage their customers. Smart package can also improve the customer experience by providing personalized content or special offers.

What is smart packaging?

The term refers to a type of packaging enhanced using technologies to connect the physical world through the digital medium. It is a revolutionary way to extend shelf life, monitor the freshness of products, and ensure safety while also improving product quality.

The innovative system offers new business opportunities by embracing Industry 4.0 and finds application across industries, from food distribution to pharmaceuticals.

As mentioned previously, deploying internet-connected technologies allow brands to provide information about their products by sending out signals through embedded sensors.

Beyond diagnostic and indicator functions, Web-to-Packaging also assists in tracking products across a warehouse or store

Smart packaging: opportunities and challenges in 2024

Maintaining the quality and safety of food and pharma products is necessary. Antimicrobial packaging, for instance, has the potential to keep items safe from contamination.

On the other hand, innovative packaging is designed to interact with its contents to maintain the quality of contents and improve their shelf life. The packaging comprises active materials or light filtering materials that absorb oxygen and regulate moisture.

Further research is being conducted to use biodegradable materials for the packaging to make it sustainable and reduce waste. Temperature tracking of perishable goods can be done by integrating thin-film electronics into printed and flexible sensor systems.

Though research is ongoing for the same but performance is still an issue. Science has given us new hope for the future, including web-to-print software for businesses in the packaging industry.

Scientists are working hard to create safer and more environmentally friendly packaging systems that can be used with sensors embedded within them. Here are three opportunities that packaging manufacturers should not miss:

A. Nanotechnology

B. Real-time capabilities

Real-time capabilities help expand the potential of a reliable Industrial Internet of Things (IoT) infrastructure and the associated communication technologies.

Still, further advancement and improvement in connectivity are needed to effectively utilize sensors embedded into both the Web-to-Packaging and all supply chain components.

The creation of cyber-physical production and delivery networks will enable packaging technologies to monitor, manage, and control the conditions of goods in real-time. The capability will significantly affect food safety, consumer health, and waste reduction.

C. Cybersecurity

Current cybersecurity and data privacy issues limit the potential of innovative packaging as an exciting application for Industry 4.0. New methodologies involving autonomic detection can help achieve adequate protection against cyberattacks.

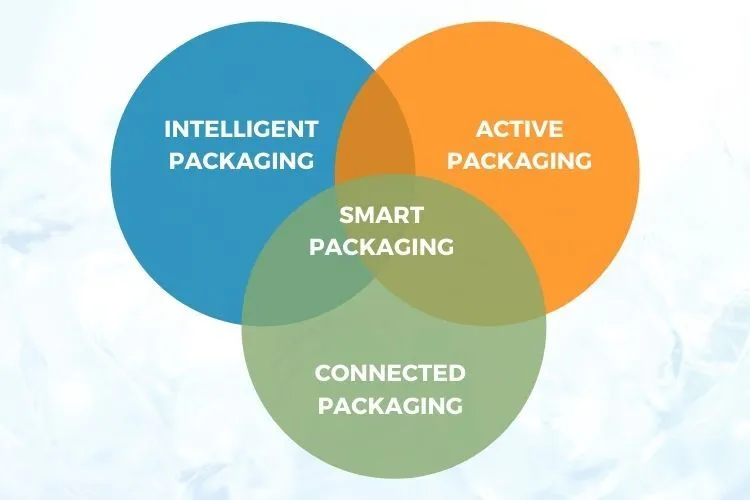

Primary types of smart packaging

Web to print software for businesses in the packaging industry has been making rounds for the last decade. While the solutions allow businesses to design their packaging in a certain way, they can still make use of two types of innovative packaging.

1. Active packaging

Active packaging interacts with the components of the pack to either maintain the quality of the products or extend their shelf life. For example, oxygen scavengers can remove the gas from sealed packages, preventing food from rotting.

Some active web-to-packaging also includes sensors that detect when a product has gone bad and trigger an alert accordingly. Different elements are used in active packaging depending on the product and its purposes.

From light filtering materials and oxygen absorbers to ethylene absorbers and antimicrobial coating, there are too many common choices to choose from in the market.

2. Intelligent packaging

Intelligent packaging solutions is oriented towards establishing external communication. It provides added diagnostic and indicator functions. Additionally, it can help with automation functions across the production line and supply chain.

Web-to-packing is empowered through barcodes, LEDs, augmented reality, radio chips, or NFC to help with easy scanning for checking ingredients and automatic reordering. It also helps with product marketing by engaging with customers.

Sensors and indicators inside packaging keep track of the product’s condition and relay pertinent information to the user. It might include freshness, tightness, temperature, or storage duration. For instance, the packaging may change color to indicate leakage or contamination.

Here’s a look at the key benefits of smart packaging:

We have seen significant advancement in intelligent packaging technology in the past five years. Both businesses and manufacturers have made headway via packaging for the sake of their bottom lines and consumer loyalty.

The key benefits of smart packaging include:

- Improved customer experience

- High-quality maintenance

- Fulfilled customer expectation

- Theft and counterfeit prevention

- Better repurchase prediction

- Robust brand loyalty

- Increased customer engagement

1. Improved customer experience

Web-to-Packaging offers a new kind of experience for the customer. With QR codes, RFID, and NFC-powered intelligent packages, brands can provide customers information about their products, ensuring greater transparency than ever before.

It empowers the customers to make an informed buying decision by providing access to information that may otherwise go unnoticed when shopping in-store. With quick access to product knowledge, customers can compare products in real-time and buy what suits their needs best. That is what makes packaging intelligent now.

2. High-quality maintenance

Smart packaging is a growing trend across industries. It can be used to monitor and indicate contamination in a product. In some cases, it may even extend the shelf life of the ingredients. Suppliers and customers have easy access to genuine quality products through handy indicators.

3. Fulfilled customer expectations

Businesses must constantly meet customer expectations, and thus investing in emerging technologies is inevitable. They must determine the best practices that can positively impact the customer experience while maintaining the bottom line of the business.

Web-to-Packaging initiatives help customers find products across the store quickly. These measures may seem expensive initially, but they drive satisfaction in the long term.

Businesses can build a competitive advantage around their offerings by elevating the in-store experience through quicker and better services.

4. Theft and counterfeit prevention

Businesses get the opportunity to protect their brand, profits, and reputation by utilizing smart packaging solutions. They can control the circulation of false products being sold under a company’s name or logo, which can ruin their reputation.

They can also clear any misconceptions among customers and prevent loss of sales opportunities. Smart packaging solutions allow businesses to monitor inventory through transit and ensure the safety of products.

They can track any missing items and ensure only genuine products reach the store. Communicating the authenticity and detailed information on boxes, consumers know exactly what they are purchasing and where these products come from.

Learn more about How To Give Your Printing Business A Competitive Advantage

5. Better repurchase prediction

Companies can predict and capture customers’ orders with Web-to-Packaging once they run out of a product. Packages with IT-enabled features help gather information and analyze it to predict best-selling print on demand products during a specified period.

Companies can plan their stock in advance and even notify customers about the availability of fresh stock. One can integrate QR codes or other cloud-based solutions into the packaging to empower customers to reorder. It can be generated using any dynamic QR code generator available in the market.

They would be redirected to a website or ordering page to order the product, thus saving their time quickly.

6. Robust brand loyalty

The modern consumer has more choices than ever, and they consider many details when picking products. They prefer purchasing products made using organic ingredients and through sustainable processes.

Studies even predict that customers are comfortable paying more for products that come in eco-friendly packaging. Therefore, brands that focus on ethical practices build a more loyal customer base.

Through smart packaging, they can offer transparency by providing details of the origin of ingredients and manufacturing processes. Customers can use the information to make a conscious decision to associate with the brand and purchase their products.

7. Increased customer engagement

Businesses need to educate customers about the potential of their products. It helps them ensure their customers are happy with the purchase and use it properly to meet their ever-evolving needs.

Smart packaging helps them learn about the products they are buying. QR codes can be integrated on packaging to direct customers to web-linked informational videos, tutorials, and self-service manuals.

Providing the information helps them save time on customer service calls and increases satisfaction rates.

Smart Packaging Trends

- The packaging industry is on a constant quest to find ways of keeping up with the ever-changing needs and wants of customers. Rapid urbanization is leading to a higher demand for personalized items. Advanced integrated innovation allows businesses to reach out to undiscovered geographical markets while providing consumers with easier access points to buying precisely what they need.

- The food and beverage industry has been proliferating, with the exploration of new technologies such as nanotechnology bringing about exciting changes in how we consume our foods. The increasing popularity of packaged goods also raises demand for products with better shelf life and sustainable packaging. The trend will also lead to less wastage and safer consumption.

- The developments in printing processes have been drivers for this market. Printed technologies can prove their functionality when it comes to the processing and presenting information on paper or other substrates like plastics and metal foil. There has recently been a lot of scientific research about how they can work best together. For instance, using an RFID tag inside the package and enhanced durability leads to new smart application possibilities in the packaging design.

- Nevertheless, the high cost of capital and security issues that come with the installment of smart packaging are key hindrances to growth. Researchers also need new techniques for fabricating sensors compatible with current packaging standards. They also need awareness among companies to drive major investments into these technologies.

Smart Packaging in the Packaging Industry

Smart packaging has a variety of benefits, both environmental and psychological. Companies must rush to identify technologies that work for their products. They should be quick enough to adopt the change to achieve an edge over competitors. Customers would also need to be acclimatized to the new packaging and its perks.

If you are looking to make a decision on the best packaging design software, you have come to the right place. Design’N’Buy can help meet your custom printed packaging requirements adequately. Contact us today!

FAQ

Most frequent questions and answers

Smart packaging helps both businesses and consumers to track where the product materials and ingredients are sourced from, where and by whom they are manufactured, and other details that might be relevant to decide whether the product is an ethical purchase.

There is none. Smart packaging is actually an umbrella term that refers to a type of packaging enhanced using technologies to connect the physical world through the digital medium. Intelligent packaging simply comprises sensors for finding out a product’s condition.

By using digital technologies such as 3D printing or scannable stickers, brands are trying to better connect with and engage their customers. Smart packaging can also improve the customer experience by providing personalized content or special offers. Plus, it helps reduce the adverse environmental impact by monitoring the product’s integrity and reducing wastage.

From improved customer experience and high-quality product maintenance to fulfilled customer expectations and theft and counterfeit prevention and better repurchase prediction to increased customer engagement and brand loyalty.

The developments in printing processes have been drivers for the packaging market. Printed technologies can prove their functionality when it comes to the processing and presenting information on paper or other substrates like plastics and metal foil. In addition, the increasing popularity of packaged goods raises demand for products with better shelf life and sustainable packaging. The trend will also lead to less wastage and safer consumption.

More for you:

The Impact of Innovative Packaging Printing and Trends in Australia 2024…Read More

Holiday Packaging Boxes: Tips for Packaging Printers on Selling Custom Packaging Boxes…Read More

How to Streamline Packaging Artwork Creation and Prototyping: A Guide for Cosmetic Packaging Designers…Read More

19 Types of Packaging Boxes for Online Custom Packaging Businesses…Read More

*This post has been updated on Jan 2024.